This "sticker" has some critical safety information you should know. I don't expect you to memorize all the information but I strongly suggest you snap a picture of the sticker, keep it on your phone, and know where to find it. It has information that is critical when it comes time to knowing the proper tire inflation and when you are shopping for replacement tires.

First the basics. The Vehicle Certification label may be an embossed metal plate or a printed sheet or a sticker. Years ago (before about 2010) the label could be almost anywhere in or on your vehicle. I have hears stories of people finding them in the glove box, in the car trunk lid or on the side of the passenger door. The best I ever heard about was on the inside of an RV closet door that could only be seen if you were standing inside the closet with both the sliding doors closed. It seemed that some felt it was a game of Hide and Seek. Luckily this has changed. DOT now has specific requirements for the information on the label and the location of the label.

Motor Vehicles: Cars, trucks and Motorhomes with driver doors. The sticker must be on the door jam of the driver door. If there is no door as with many Class-A motorhomes the label must be near the driver left elbow and visible from the driver's seat.

Trailers; The label must be on the driver side, outside, toward the front of the trailer.

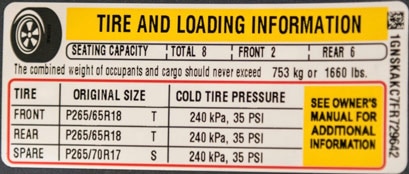

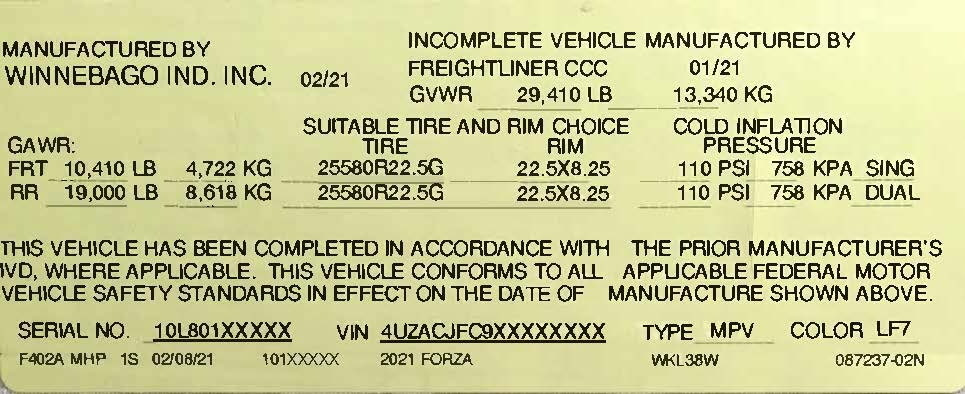

What information is on the Label: Tire Size, Load Range, Grose Axle Weight Rating or GAWR and cold inflation of the tires. Many also have VIN along with other information.

Currently DOT requires the inflation be the minimum inflation needed to support the GAWR. As of 2017 RVIA added a requirement that tires be inflated to a level that included a margin of 10% so if your RV MFG certifies your RV to be in compliance the RVIA standards that would be the inflation shown on the label. If tire size or inflation is different for an axle the information must be shown for each axle.

Here are some examples of the sticker found on the Internet.

Some RVs have more than one label

Below is a label from an SUV

##RVT1037